by Lloyd Alter

The economist John Maynard Keynes purportedly stated,

“When the facts change, I change my mind. What do you do, sir?”

I’m contemplating altering my thoughts about 3D printed homes. I wrote eight years in the past: “I am not a total skeptic about 3D-printed houses. I think there is a place for them—on the moon, for example.” The primary commenter famous: “What a stupidly conservative view… the article is absolute garbage.”

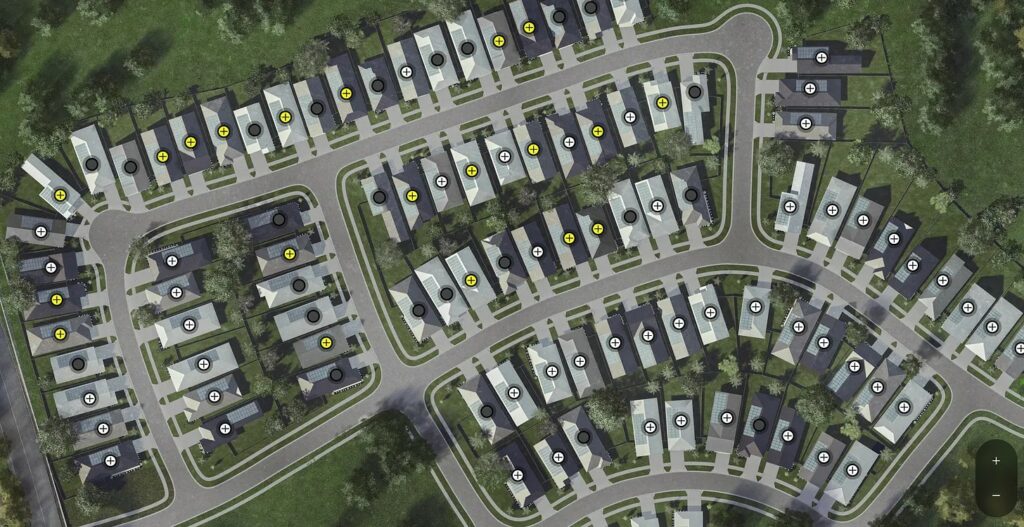

Maybe he was proper. Final yr in this area I checked out a 3D printed subdivision in Texas, Properties at Wolf Ranch, constructed by ICON and the large developer Lennar, all “co-designed” by Bjarke Ingels Group. I used to be compelled to confess then that this was trying promising, concluding, “perhaps I shouldn’t be such a stupidly conservative curmudgeon.” Now, in accordance with Reuters, the subdivision is nearly full, and ICON touts the benefits:

“It brings a lot of efficiency to the trade market,” stated ICON senior venture supervisor Conner Jenkins. “So, where there were maybe five different crews coming in to build a wall system, we now have one crew and one robot.”

This isn’t precisely true; they’ve 5 robots, and it takes three weeks to print the partitions of a one-storey home, which isn’t precisely quick. However they are saying, “compared to traditional construction, the company says that 3D printing homes is faster, less expensive, requires fewer workers, and minimizes construction material waste.”

There may be additionally an enormous capital funding right here, in comparison with standard development, they usually should feed the machines. In accordance with Reuters,

“Developers said a little more than one quarter of the 100 homes have been sold.”

This isn’t how subdivisions often get constructed; conventionally, patrons get to choose their plans after which the home will get began. Somebody is placing some huge cash upfront right here and taking massive dangers; at $500K per home they’re sitting on $37.5 million in stock.

Now, let’s look on the brilliant aspect. These properties are stable, and actually quiet. if the conventionally framed roofs are tied down correctly, they are going to be immune to water, mould, termites and excessive climate. One house owner says “It feels like a fortress.” Apparently, the most important drawback they’ve is getting a great WIFI sign via the partitions, with the house owner telling Reuters:

“Obviously these are really strong, thick walls. And that’s what provides a lot of value for us as homeowners and keeps this thing really well-insulated in a Texas summer, but signal doesn’t transfer through these walls very well.”

The plans, based mostly on profitable, standard Lennar designs, aren’t unhealthy, should you can settle for the inevitable two automotive storage. No less than it isn’t a snout protruding; there’s a bed room on the entrance which may act as a house workplace. I just like the rounded corners all over the place. (Take a 3D video tour right here)

The ribbed partitions are going to in all probability be a difficulty with mud assortment, (and a greasy catastrophe behind the fuel range within the kitchen, which ought to NEVER have a combo microwave fan above, however that’s one other kvetch) however I just like the look of them. The properties are apparently low-cost to run; in accordance with Development Briefing,

“We got a utility bill from one of the customers there from last week,” stated [ICON construction VP Spencer] Padgett. “For a 1,850 sq ft house, [the energy bill was] $35 for the entire month. It doesn’t rot, there’s no bugs that are going to eat it, it’s not effected by humidity,” continued Padgett, noting benefits. “The walls are just stronger.”

What’s to not love?

For one factor, it’s a carbon bomb. The homes are in a car-dependent suburb of Austin, and being single household dwellings, have much more exterior wall. It’s a system designed for sprawl, given the problem of doing second flooring.

Then there may be the concrete they’re squirting out; as Brian Potter of Development Physics famous,

“3D printable mixes differ from traditional concrete in that they have no large aggregate, only sand (making them more like grout than concrete). They also have very large fractions of cement or cementitious materials – they seem to hover around a ratio of 1:2 between cement and aggregate, compared to a 1:7 ratio for more traditional concrete.”

As I famous in my prior put up, “The walls here are thinner than poured concrete, so there is less of it, but then they are pouring all the interior walls out of the stuff as well, and pound for pound, it is almost solid CO2.”

I’m biased in the direction of pure supplies like wooden and straw, however that is Texas. I want larger densities and multi-storey designs, however ICON is engaged on that too, with a brand new Phoenix printer that may attain up 27 toes and do roofs.

However I’m not satisfied that this could scale; these are costly machines and they aren’t significantly quick, and there’s something humorous in regards to the cash, this isn’t the traditional improvement mannequin.

Whereas the Properties at Wolf Ranch have standard plans in a subdivision, ICON can also be working with Bjarke on a venture in West Texas with wild plans that reap the benefits of the liberty that the printer permits, doing curvy varieties “made possible by the capabilities of ICON’s 3D printing technology while adding strength and beauty to the overall structure.”

Right here is why I’m so conflicted. ICON and Bjarke are pushing the technological and design envelope. However these are massive second properties fabricated from concrete miles from wherever, really carbon H-bombs. The emissions from making the properties and driving to them immediately contribute to local weather change, and who is aware of if this a part of Texas will even be liveable in just a few years.

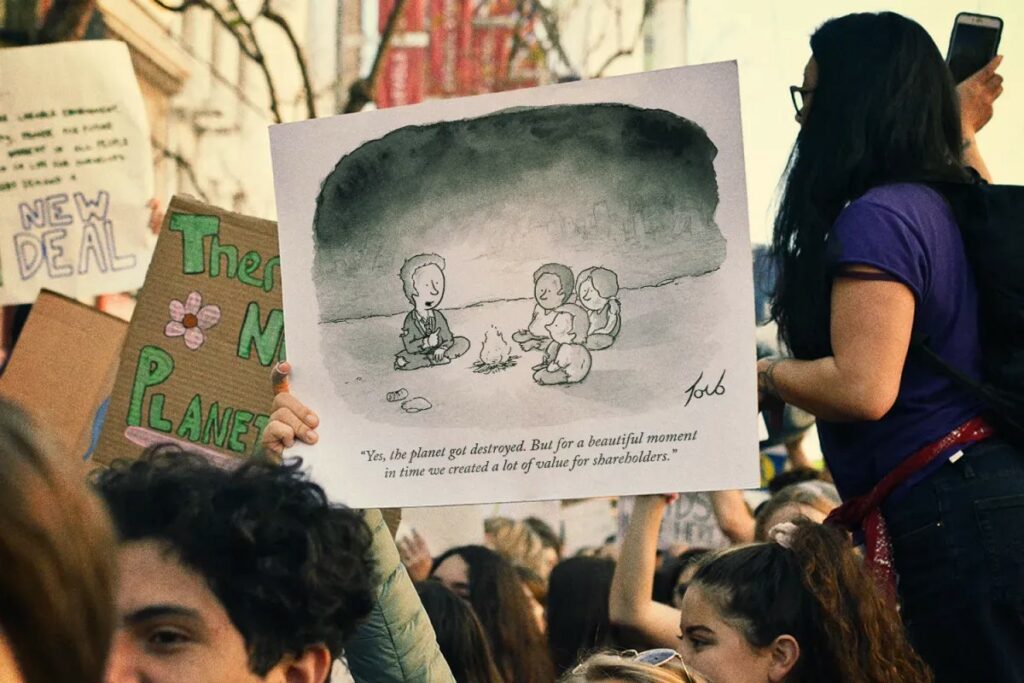

To paraphrase the nice 2012 Tom Toro cartoon within the New Yorker,

“Yes, the planet got destroyed. But for a beautiful moment in time before it got too hot, we built some neat concrete houses in the desert and had some great parties.”